Open Frame Power Supplies

Looking for an open frame power supply? You’ve come to the right place. Here at Bravo Electro, we offer a wide variety of open-frame power supplies for any industry. Shop top brands like Mean Well at the lowest prices online today.

Read more

Find Quality, Reliable Open Frame Power Supply Products At Bravo Electro

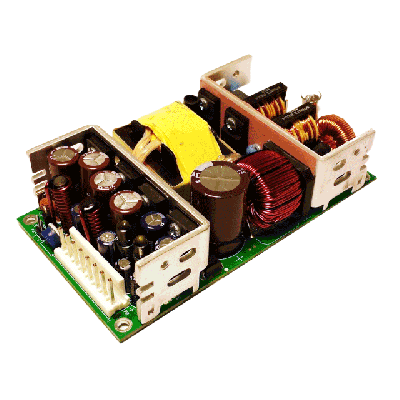

These types of AC DC power supplies typically feature a PCB-only construction. The power supplies are integrated into an end application to provide an enclosure for the entire product. And if you’re in the market for power supply products, you need the best of the best. For reliable open frame power supply products, look no further than Bravo Electro.

We’ve earned the reputation as the #1 place to get all your electrical components, which also includes fans and piezos. Here, you’ll gain access to reliable products from the top manufacturers in the industry. We curate only the most well-respected brands in the industry - so you can shop with confidence here with us.

We live and breathe electrical components - so we can help you choose the right supplies if you’re not quite sure what you need. If you need something custom built, reach out. We have engineers on staff to talk shop with you and bring your vision to life.

Why Shop With Us?

What makes Bravo Electro’s open frame power supply collection standout? Here are some of the most noteworthy features:

- High efficiency - up to 95%

- Built-in active PFC function

- Protected from short circuit, overload, and over voltage

- Cooling by free air convection

- LED indicators for operating status

- Ultra-low no-load power consumption

Many of our electric components come with outstanding warranties of up to 3 years. But, that’s not the only benefit of choosing Bravo Electro - we can also help you with custom projects. Just reach out if you have questions or need assistance.

We Offer Much More Than Just Open Frame Power Supply

Looking for something else? Chances are, we have it. After all, we are the leading supplier of electrical components! Any type of AC DC power supply you need, we’ll get it for you. We also have enclosed power supplies, external power supplies, and even medical power supplies. If you’re looking for specific voltages, here at the most popular we offer:

Not seeing what you’re looking for? That doesn’t mean we don’t have it - just reach out with any questions. You can simply send us your power supply requirements and our Power Experts send back a list of your options within the same day - it is really that easy. Shop now and enjoy same-day shipping with orders placed before 2 pm PST!

IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 7.5/ -7.5/ 12/ 12VDC, Output Current: 3/ 2/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4010 is a quad output, AC-DC power supply. The four outputs are 7.5V / 3A, -7.5V / 2A, 12V / 2A, 12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4010 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 6.7/ 5/ 15/ -15VDC, Output Current: 5/ 4/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4009 is a quad output, AC-DC power supply. The four outputs are 6.7V / 5A, 5V / 4A, 15V / 2A, -15V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4009 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 24/ 15/ -15VDC, Output Current: 6/ 2/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4007 is a quad output, AC-DC power supply. The four outputs are 5V / 6A, 24V / 2A, 15V / 2A, -15V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4007 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 24/ 12/ -12VDC, Output Current: 6/ 2/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4006 is a quad output, AC-DC power supply. The four outputs are 5V / 6A, 24V / 2A, 12V / 2A, -12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4006 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ -5/ 15/ -15VDC, Output Current: 6/ 5/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4005 is a quad output, AC-DC power supply. The four outputs are 5V / 6A, -5V / 5A, 15V / 2A, -15V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4005 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ -5/ 12/ -12VDC, Output Current: 6/ 5/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4004 is a quad output, AC-DC power supply. The four outputs are 5V / 6A, -5V / 5A, 12V / 2A, -12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4004 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 3.3/ 15/ -15VDC, Output Current: 6/ 5/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4003 is a quad output, AC-DC power supply. The four outputs are 5V / 6A, 3.3V / 5A, 15V / 2A, -15V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4003 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 3.3/ 12/ -12VDC, Output Current: 6/ 5/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4002 is a quad output, AC-DC power supply. The four outputs are 5V / 6A, 3.3V / 5A, 12V / 2A, -12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4002 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Quad Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 3.3/ 5/ 12/ -12VDC, Output Current: 6/ 5/ 2/ 2A

More Details

The Integrated Power Designs REL-70-4001 is a quad output, AC-DC power supply. The four outputs are 3.3V / 6A, 5V / 5A, 12V / 2A, -12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-4001 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$95.01 As low as $88.92IPD Triple Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 18/ 18VDC, Output Current: 5/ 2/ 2A

More Details

The Integrated Power Designs REL-70-3005 is a triple output, AC-DC power supply. The three outputs are 5V / 5A, 18V / 2A, 18V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-3005 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$92.49 As low as $86.56IPD Triple Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 3.3/ 7/ 12VDC, Output Current: 6/ 5/ 2A

More Details

The Integrated Power Designs REL-70-3004 is a triple output, AC-DC power supply. The three outputs are 3.3V / 6A, 7V / 5A, 12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-3004 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$92.49 As low as $86.56IPD Triple Output AC-DC Converter, Open Frame Package, 61 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5.1/ 7.5/ -7.5VDC, Output Current: 6/ 2/ 2A

More Details

The Integrated Power Designs REL-70-3003 is a triple output, AC-DC power supply. The three outputs are 5.1V / 6A, 7.5V / 2A, -7.5V / 2A for a total power output of 61 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-3003 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$92.49 As low as $86.56IPD Triple Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 15/ -15VDC, Output Current: 6/ 2/ 2A

More Details

The Integrated Power Designs REL-70-3002 is a triple output, AC-DC power supply. The three outputs are 5V / 6A, 15V / 2A, -15V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-3002 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$92.49 As low as $86.56IPD Triple Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 5/ 12/ -12VDC, Output Current: 6/ 2/ 2A

More Details

The Integrated Power Designs REL-70-3001 is a triple output, AC-DC power supply. The three outputs are 5V / 6A, 12V / 2A, -12V / 2A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-3001 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$92.49 As low as $86.56IPD Dual Output AC-DC Converter, Open Frame Package, 70 Watts, Input Voltage Range: 85~264 VAC, Output Voltage: 9/ 48VDC, Output Current: 2/ 1.5A

More Details

The Integrated Power Designs REL-70-2008 is a dual output, AC-DC power supply. The two outputs are 9V / 2A, 48V / 1.5A for a total power output of 70 watts. It accepts an AC input range of 85~264 and has an efficiency rating of 0.87%. The REL-70-2008 is an Open Frame package type with an operating temperature range of 0C to +70C. This AC-DC converter has Medical and Industrial (ITE) safety certifications, no on board fan and its dimensions are 4.5 (L) x 2.5 (W) x 1.22 (H) inches. If you have questions about this IPD power supply please contact us through our web chat (lower right hand corner) or call us (408-733-9090).$90.47 As low as $84.67